Expert Insight from Rocon Foam

At Rocon Foam, we provide custom foam die cutting services for UK industries seeking speed, accuracy, and repeatability in their production lines. Backed by decades of foam engineering expertise, we know how vital the right cutting technique is for reducing waste, increasing throughput, and improving product performance. This is why foam die cutting remains one of the most important tools in our industrial offering.

What Is Foam Die Cutting?

Foam die cutting is a manufacturing process that uses precision-engineered dies to shape foam into specific sizes or forms. These dies are designed from metal and used repeatedly to deliver uniform, accurate results with high speed and minimal error.

This method works with a wide range of materials, including:

- Open-cell polyurethane foam

- Closed-cell polyethylene and EVA foam

- High-density and memory foam

- Fire-retardant and anti-static foam

Each foam type brings specific qualities, but the precision and repeatability of die cutting makes it the best choice for high-volume, low-waste production.

Benefits of Foam Die Cutting for Production Efficiency

1. Fast, Repeatable Manufacturing

Die cutting enables rapid processing of identical foam parts, making it ideal for large production runs. This streamlines workflows and allows your team to focus on quality control rather than manual cutting.

2. Consistency with Tight Tolerances

Precision is vital in packaging, insulation, and product assembly. Die cutting achieves consistent results, meeting tight tolerances every time. The outcome? Fewer rejected parts and higher end-product quality.

3. Reduced Material Waste

Manual cutting can result in offcuts and unusable foam. Die cutting minimises waste, making it an eco-conscious, cost-saving method that optimises raw material usage.

4. Compatibility with Complex Shapes

Need intricate shapes or tight internal cutouts? Custom foam die cutting services allow for complex designs that would be difficult or impossible to replicate by hand or with CNC alone.

Industry Applications of Foam Die Cutting

Packaging and Shipping

Foam die cutting for packaging produces inserts that cradle fragile goods, keeping them safe during transit. With custom contours and perfect fit, items stay protected while minimising shipping damage.

Automotive and Aerospace

Sound insulation, seating supports, and vibration dampening materials in vehicles are often die-cut foam components. Their precise shapes ensure compatibility and performance within tight tolerances.

Medical and Healthcare

Surgical padding, cushioning for diagnostic equipment, and medical-grade foam inserts rely on the consistent shape and hygiene suitability of foam die cutting.

Consumer Goods and Retail

From foam-backed retail displays to product trays and promotional packaging, precision die-cut foam inserts add a layer of professionalism and protection.

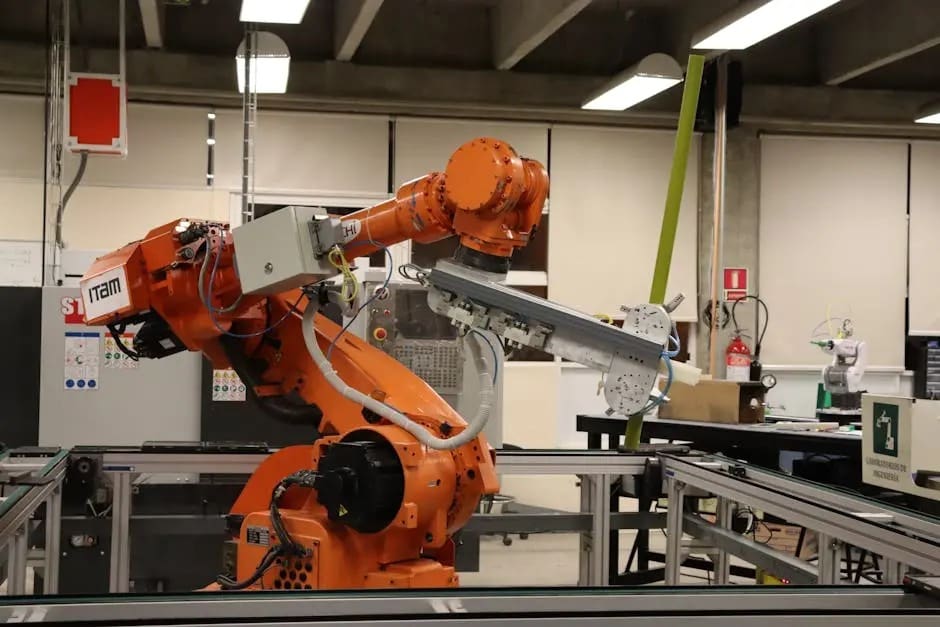

Industrial Machinery and Tooling

Custom gaskets, spacers, and housing pads made from die-cut foam provide consistent sealing and vibration control in manufacturing environments.

Choosing the Right Foam for Die Cutting

Every application demands specific foam characteristics. Our team advises on selecting the right type of foam based on performance needs:

- Open-cell foams provide breathability and light cushioning

- Closed-cell foams offer moisture and chemical resistance

- Memory foams deliver superior comfort and pressure distribution

- EVA and polyethylene foams are perfect for rigid, protective inserts

We match each die-cutting project to a foam grade that balances cost, functionality, and longevity—ensuring you get the most from your investment.

Best Practices for Implementing Foam Die Cutting

Evaluate Your Process First

Identify bottlenecks, inconsistent cuts, or wasteful offcuts. These signal where foam die cutting can provide real, measurable improvements.

Engage with Experienced Manufacturers

Work with suppliers who understand your industry requirements. Rocon Foam offers both prototyping and full-scale production, guiding you from design to delivery.

Ensure Staff Know the Process

If die cutting is done in-house, training operators on tool safety, maintenance, and handling is key. Otherwise, outsourcing to a trusted UK foam converter like Rocon can save time and resources.

Collaborate on Design

Early involvement with your foam supplier helps refine the design for cutting efficiency. Together, we can adjust thickness, layout, and nesting to improve output and reduce waste.

Sustainability Advantages of Die Cutting

Sustainability isn’t just about materials—it’s also about reducing waste. Foam die cutting production efficiency ensures you use only what’s needed, with minimal surplus. Combined with recyclable and biodegradable foam options, it’s a smarter, greener solution for forward-thinking manufacturers.

Why Work with Rocon Foam?

We are specialists in industrial foam conversion solutions. Whether you’re building a new product line or seeking to improve existing workflows, Rocon Foam offers:

- UK-based foam design and manufacturing

- Fast delivery and flexible production runs

- Custom die creation and material matching

- ISO9001-certified quality assurance

- Expert consultation on foam materials and cutting techniques

Our team supports you at every stage—ensuring your project stays on time, on budget, and on brief.

FAQs About Foam Die Cutting

What’s the lead time for a die-cutting project?

Depending on the complexity, our average lead time is 7–10 working days from design approval.

Can I get foam prototypes before committing to a bulk order?

Yes. We offer prototyping to help refine dimensions, test material performance, and ensure confidence before scaling up.

Is die cutting suitable for small-batch runs?

Absolutely. While great for high volume, our tools can also be adapted for short-run or one-off projects.

What industries benefit most from die cutting?

Packaging, automotive, healthcare, aerospace, and electronics are key sectors—but any industry needing consistent, efficient foam shapes can benefit.

Improve Your Production Efficiency with Rocon Foam

If you’re looking to reduce waste, improve speed, and achieve precision foam shaping at scale, foam die cutting is your next step forward. Rocon Foam can help you design, cut, and deliver a solution that fits your business perfectly.

📞 Contact Rocon Foam

Phone: 01905 26616

Email: roconfoam@gmail.com

Address: Unit 14 Shrub Hill Ind. Estate, Tolladine Road, Worcester WR4 9EL