Polyurethane foam is widely used due to its thermal performance and versatility. It is sustainable, comfortable, and offers protection. Made by reacting polyols and diisocyanates, it has various applications such as furniture, insulation, and packaging. Rocon Foam provides custom-cut solutions and is a leading supplier of polyurethane foam.

Polyurethane foams are in many daily applications, whether you are at home, at the gym, or in the office. It is one of the most widely used foams on the market. This is usually down to the foam’s excellent thermal performance and airtightness. Polyurethane is a versatile, modern, and safe foam that has countless applications, from building and construction to industrial products and basic consumables. It is highly versatile, and makes lives more convenient, comfortable, and environmentally friendly.

Related: Looking for class 0 acoustic foam? Try Rocon Foam!

Why should you use polyurethane foams?

Polyurethane foams often referred to as PU foams, are highly durable but also sustainable, offering comfort and additional protection to our lives.

Five core reasons to use polyurethane foam is listed below:

-

- Sustainability – polyurethanes help to save natural resources by minimising the need to consume more energy.

- Comfort – the many ways polyurethanes add comfort to our lives, particularly in the furniture and insulation markets which contribute to making buildings more thermally efficient.

- Versatility – there is a wide range of polyurethane applications. With such enormous adaptability, availability and of course the ability to be recycled, PU foam is the preferred foam for many industries.

- Protection – polyurethane foam offers protection, from its insulating efficiency to its use in cars.

- Durability – polyurethane products are able to keep their efficiency over time and still offer the highest level of performance depending on the application and the use of the foam. For example, in normal wear conditions, the average lifespan is over 50 years in building insulation, more than 25 years in fridges, and more than 20 years in car bumpers. In fact, polyurethane foam will usually surpass the durability of the product it is supporting.

How is Polyurethane Foam Made?

Put simply, polyurethane foams are made by reacting polyols and diisocyanates. During the manufacturing of the foam, it can be manipulated in multiple different ways in order to create variations of polyurethane foam. This also means these different types will be suitable for a wide array of applications and purposes.

Applications

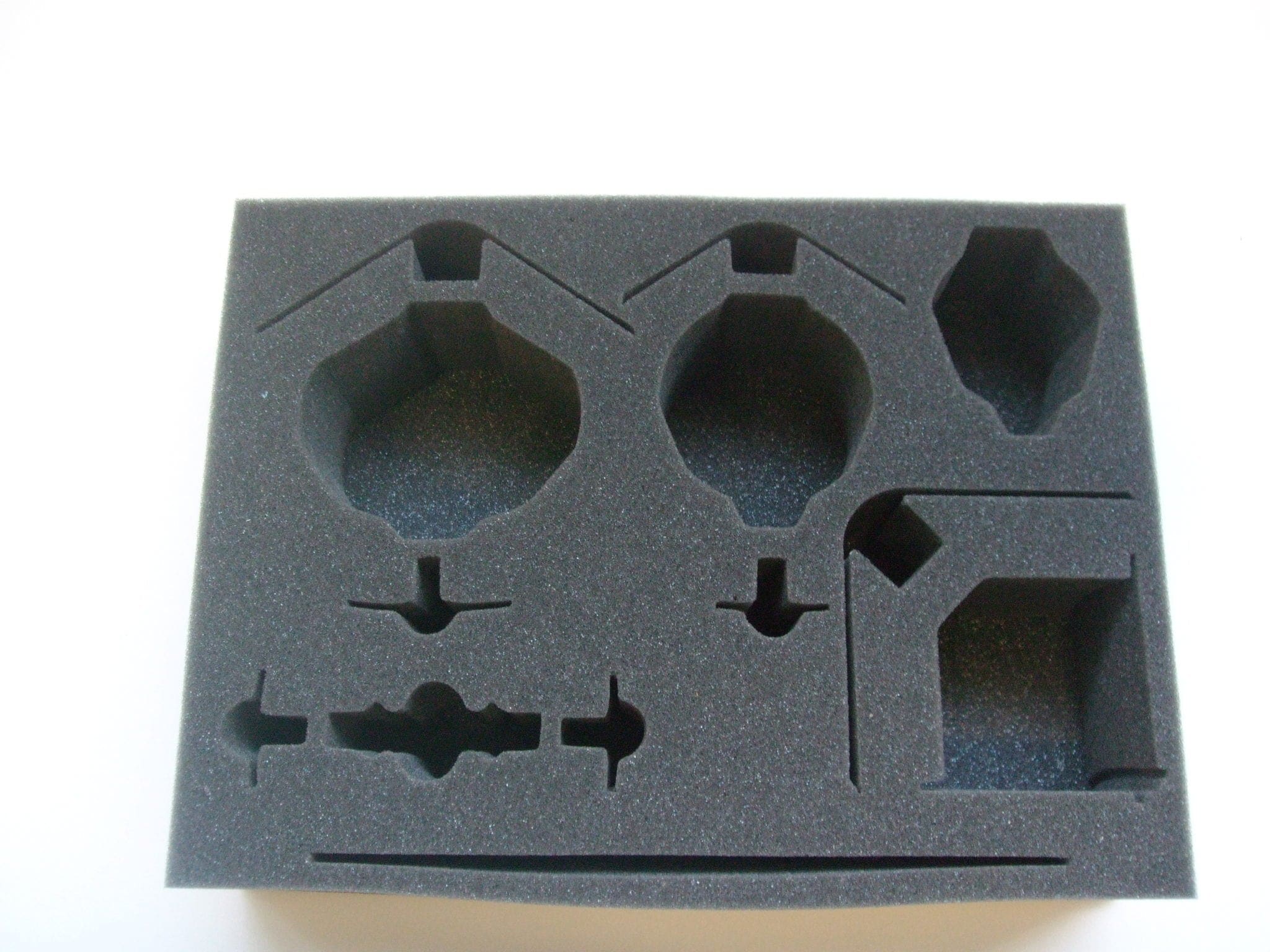

We are proud to stock a wide range of industrial foam solutions here at Rocon Foam Ltd, including polyurethane foam. Using our state-of-the-art machinery, we can cut your foam pieces to almost any size and shape. This means we can provide you with a bespoke solution that is perfect for your requirements. Some of the many applications our polyurethane supports include:

-

- Sofa cushions

- Memory foam mattresses and cushions

- Caravan and boat foam cushions

- Wheelchair cushions

- Toy stuffing

- Upholstering

- Packaging

Foam Suppliers

Here at Rocon Foam, we are one of the country’s leading foam suppliers and are committed to providing customers with a quality start to finish service that gives them everything they need and more. Our foam experts will happily talk you through everything you need to know, in order to ensure you are investing in a foam product that is perfect for your requirements.

Want to find out more about our polyurethane foams? Then call 01905 26616 to speak to a member of our helpful and friendly team.

If you have found this blog helpful, then you may wish to read our previous blog on Looking For Acoustic Foam Panels or Why Should You Choose Rocon Foam For Your Foam Packaging Requirements?